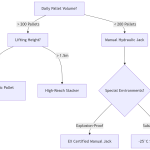

In the fields of logistics warehousing and industrial material handling, pallet trucks are one of the core tools for enhancing efficiency. The requirements for material handling equipment vary significantly across different scenarios, ranging from low clearance spaces to high-density storage, and from light to heavy loads. The choice of the right pallet truck directly affects operational efficiency and safety. This article, based on the latest industry technologies and product trends, provides an in-depth analysis of 7 types of specialized pallet trucks - High Lift Pallet Truck, Manual Pallet Truck, Hydraulic Pallet Truck, Heavy Duty Pallet Truck, Double Pallet Truck, Adjustable Pallet Truck, and Low Profile Pallet Truck. Combined with the technical features of iLiftEquip's high-lift pallet trucks, it helps you accurately match your needs.

In the fields of logistics warehousing and industrial material handling, pallet trucks are one of the core tools for enhancing efficiency. The requirements for material handling equipment vary significantly across different scenarios, ranging from low clearance spaces to high-density storage, and from light to heavy loads. The choice of the right pallet truck directly affects operational efficiency and safety. This article, based on the latest industry technologies and product trends, provides an in-depth analysis of 7 types of specialized pallet trucks - High Lift Pallet Truck, Manual Pallet Truck, Hydraulic Pallet Truck, Heavy Duty Pallet Truck, Double Pallet Truck, Adjustable Pallet Truck, and Low Profile Pallet Truck. Combined with the technical features of iLiftEquip's high-lift pallet trucks, it helps you accurately match your needs.

The high lift pallet truck is specifically designed for scenarios where pallets need to be lifted vertically, such as accessing shelves, stacking materials on assembly lines or workstations. With a lifting height typically ranging from 800mm to 5500mm and featuring scissor or hydraulic drive mechanisms, it ensures stable load handling. Its high lift capacity, stability, and flexible maneuverability make it an ideal choice for various material handling tasks.

Technical highlights (refer to iLiftEquip product):

Double-piston hydraulic system: Utilizing efficient hydraulic drive technology, it offers a smooth lifting and lowering experience, with a maximum load capacity of up to 1500kg, making it suitable for medium and heavy-duty cargo handling.

Low chassis design: The forklift's ground clearance is only 85mm, allowing it to easily insert into low pallets. The automatic locking function after lifting ensures operational safety.

Wear-resistant material: High-strength steel forks combined with polyurethane (PU) wheels reduce ground wear and are suitable for various indoor and outdoor environments.

Applicable scenarios: High-level storage and retrieval in warehouses, vertical material transportation on production lines, and e-commerce logistics centers.

2. Manual Pallet Truck

Keywords: Economy, Lightweight, Basic material handling

The manual pallet truck is operated by hand and is suitable for short-distance and low-frequency material handling. It is an economical choice for small warehouses.

Product design trends:

Ergonomic handle: Optimizes handle angle and grip feel to reduce fatigue from prolonged operation.

Lightweight structure: The all-steel frame strikes a balance between strength and portability, with a load capacity of 1000-2500kg, meeting the daily handling requirements.

Applicable scenarios: Restocking in retail stores, loading and unloading of light goods, and temporary warehousing operations.

3. Hydraulic Pallet Truck

Keywords: Power-driven, High-load capacity, Precise control

The hydraulic pallet truck achieves smooth lifting and lowering through a hydraulic system, making it suitable for heavy-duty or frequent operation environments.

Technical advantages (refer to iLiftEquip hydraulic solution):

Intelligent hydraulic valve: Precisely control the lifting speed, prevent cargo from swaying, and ensure operational stability.

Anti-slip design: Equipped with grooved PU wheels to enhance ground adhesion, especially suitable for oily or wet environments.

Applicable scenarios: Heavy component handling in manufacturing, high-frequency operations in logistics centers.

4. Heavy Duty Pallet Truck

Keywords: Super strong load capacity, industrial-grade durability

The heavy-duty pallet truck is specially designed for extreme loads and is commonly seen in industries such as steel and building materials.

Core Performance:

Reinforced structure: Thickened steel forks and reinforced chassis, with a maximum load capacity of over 3000kg.

Anti-corrosion treatment: Surface galvanization or spraying process to extend the service life of the equipment in harsh environments.

Applicable scenarios: Port container loading and unloading, heavy industrial production lines, large-scale warehousing centers.

5. Double Pallet Truck

Keywords: Efficient sorting, Synchronous handling

The double pallet truck, through its innovative structural design, can handle multiple pallets simultaneously, significantly increasing efficiency.

Application advantages:

Parallel operation: Supports simultaneous handling of double-layer pallets, reducing round-trip time, and is particularly suitable for batch sorting scenarios.

Flexible steering: Narrow body design with swivel wheels, suitable for narrow aisles between dense shelves.

Applicable scenarios: Batch sorting in e-commerce warehouses, multi-batch transportation in cold chain logistics.

6. Adjustable Pallet Truck

Keywords: Flexible Adaptation, Multi-functional Expansion

The adjustable pallet truck can be compatible with non-standard pallets or special goods by adjusting the width or height of the forks.

Customized functions:

Fork telescopic design: Supports width adjustment (e.g., from 520mm to 700mm), suitable for different sized pallets.

Adjustable height chassis: The lowest fork height can reach 35mm, easily meeting the requirements of low spaces.

Applicable scenarios: Handling of irregular pallets, integration into automated production lines, and loading and unloading in mezzanine warehouses.

7. Low Profile Pallet Truck

Keywords: Space Optimization, Narrow Scenarios

The ultra-low profile pallet truck is specially designed for low spaces, with a fork height as low as 35mm from the ground, solving the problem that traditional equipment cannot enter.Technical highlights:

Ultra-thin fork: Made of high-strength alloy material, with a thickness of only 35mm, it can easily insert into the bottom of low-clearance pallets.

Compact body: Short wheelbase design, small turning radius, suitable for car chassis loading and unloading or compact shelving.

Applicable scenarios: Automobile manufacturing workshops, mini-warehouses, mezzanine warehouses.

Conclusion

From high-lift to ultra-low placement, and from manual to hydraulic drive, the subcategories of pallet trucks are evolving towards specialization, scenario adaptation, and intelligence. Taking the iLiftEquip high-lift pallet truck as an example, its dual-piston hydraulic system and low-profile design reflect the industry's technological upgrade trend. When enterprises choose equipment, they need to comprehensively consider load requirements, space constraints, and industry standards (such as anti-corrosion or hygiene requirements). In the future, with the popularization of automation technology, pallet trucks will further integrate into intelligent warehousing systems and become a core node of Industry 4.0.